close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-11-07 Origin: Site

Expansion joints are essential components in construction and engineering, designed to accommodate the natural movements of structures caused by temperature fluctuations, vibrations, and loads. These flexible connectors prevent damage by allowing different parts of a building, bridge, or pipeline to expand and contract independently. By effectively managing stress and movement, expansion joints enhance structural integrity, safety, and longevity, making them crucial in various applications across multiple industries. Understanding their function and importance helps ensure that structures can withstand the forces they encounter over time.

Expansion joints come in various types, each designed for specific structures and applications. Understanding these types helps in selecting the right joint to accommodate movement and protect structural integrity.

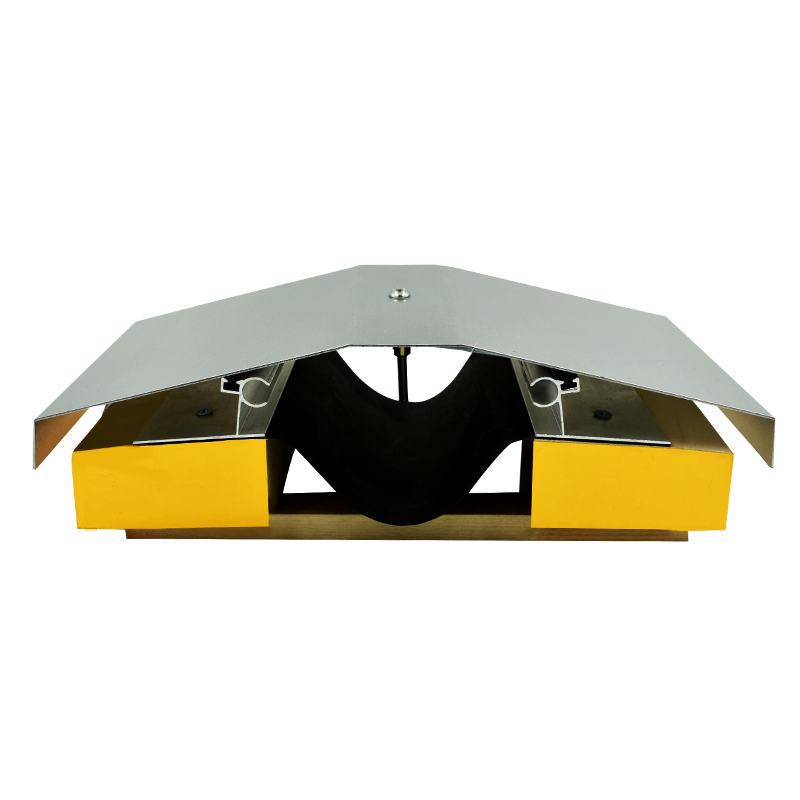

Bridge expansion joints handle movement caused by traffic loads, temperature changes, and vibrations. They allow bridges to expand and contract without cracking or damaging the deck. These joints are often made from durable materials like metal and rubber to withstand harsh weather and heavy use. Common designs include finger joints, modular joints, and strip seals, each suited for different bridge types and movement ranges.

Concrete expands and contracts due to temperature and moisture changes. Concrete expansion joints are gaps placed between slabs or between concrete and other materials. They prevent cracking by allowing slabs to move independently. These joints are typically filled with flexible materials like sealants or compressible fillers. Proper spacing and depth are crucial—usually about 30 times the slab thickness apart and at least a quarter of the slab depth deep.

Pipelines experience thermal expansion, pressure changes, and vibrations. Pipe expansion joints absorb these movements, protecting pipes and connected equipment. They often include metal bellows made of stainless steel for high strength and flexibility. Some designs incorporate hinges or gimbals for angular movement. Industries like power plants, oil refineries, and chemical factories rely heavily on these joints to maintain system integrity and reduce maintenance.

Rubber expansion joints are flexible, cost-effective solutions that absorb vibrations, noise, and movement. They are common in HVAC systems, water lines, and industrial piping. Their elasticity helps reduce stress on connected equipment. Rubber joints can handle moderate temperatures and pressures and often include fabric reinforcements for added strength. They are easy to install and maintain.

Metal expansion joints, typically made from stainless steel or other alloys, are designed for high-temperature and high-pressure environments. They provide excellent resistance to corrosion and mechanical stress. These joints are used in power generation, petrochemical plants, and aerospace applications. Their bellows can absorb axial, lateral, and angular movements, making them versatile for complex piping systems.

Selecting the appropriate expansion joint type depends on the structure’s movement type, environmental conditions, and operational demands to ensure long-term performance and safety.

Expansion joints play a crucial role in maintaining the safety, durability, and functionality of many structures. They manage movements caused by temperature changes, loads, seismic activity, and other forces. Without them, buildings, bridges, pipes, and other constructions would suffer serious damage.

Materials expand and contract as temperatures rise and fall. This constant movement puts stress on structures. Without expansion joints, this stress can cause cracks, warping, or even breakage. For example, concrete slabs without joints may crack when they expand in the heat. Similarly, steel pipes under thermal stress can bend or rupture if not equipped with flexible joints. Expansion joints absorb these movements, preventing damage and maintaining structural integrity.

Safety is a top priority in construction and engineering. Expansion joints reduce the risk of sudden failures caused by material fatigue or stress buildup. In bridges, joints allow decks to move slightly during traffic loads or temperature shifts, preventing dangerous buckling or cracking. In pipelines, joints reduce stress on connections to pumps or turbines, lowering the chance of leaks or bursts. By controlling movement, expansion joints protect both the structure and its users.

Structures that can handle movement last longer and need fewer repairs. Expansion joints reduce wear and tear caused by vibration, pressure, and thermal changes. This means less downtime for maintenance and lower overall costs. For example, industrial plants use metal expansion joints in high-temperature pipes to prevent early failure. Similarly, buildings with properly installed wall and floor joints avoid costly cracks and water damage. In the long run, expansion joints save money by extending service life.

Regularly assess the expected movement range and environmental conditions to select expansion joints that best protect your structure from damage and ensure safety.

Expansion joints play a vital role across many industries and types of construction. They allow structures to move safely without damage, even under stress from temperature changes, loads, or seismic forces. Here’s a closer look at where expansion joints are commonly used and why they matter.

Bridges and highways face constant movement due to traffic loads, weather shifts, and thermal expansion. Expansion joints in these structures absorb this movement to prevent cracks and deformation. For example, a bridge deck expands on hot days and contracts when cold. Without joints, this could cause the deck to buckle or crack. Specially designed bridge expansion joints, like modular or finger joints, ensure smooth vehicle travel while accommodating movement.

Buildings, especially large ones, experience movement caused by thermal changes, wind sway, and settling. Expansion joints in walls, floors, and ceilings help manage this movement. Parking structures face heavy vehicle loads and temperature swings, making expansion joints essential to avoid stress cracks. These joints also maintain waterproofing, fire resistance, and soundproofing functions while allowing safe movement between building sections.

Pipelines transport fluids under pressure and temperature variations. Expansion joints absorb pipe expansion, contraction, and vibrations, protecting connections and equipment. In industrial plants or water treatment facilities, they prevent leaks and pipe damage. Metal bellows or rubber joints are common, chosen based on pressure, temperature, and chemical exposure. Properly installed joints reduce maintenance needs and downtime.

Factories often use complex piping and duct systems that expand, contract, or vibrate during operation. Expansion joints accommodate these movements, protecting machinery and structural elements. They are critical near boilers, turbines, and pumps, where thermal stresses are high. Rubber and metal joints are popular choices, customized for specific industrial environments. These joints improve safety and extend equipment life.

When planning projects, identify all points of likely movement and specify expansion joints tailored to each application's unique environmental and operational demands.

Expansion joints are essential components that provide several key benefits in construction and industrial applications. They help structures cope with movements caused by temperature changes, loads, vibrations, and other forces. Let’s explore the main advantages of using expansion joints.

Expansion joints absorb movement and stress in materials, preventing cracks, warping, or breaks. Without them, thermal expansion or contraction could cause concrete slabs to crack or steel pipes to bend. By allowing parts of a structure to move independently, expansion joints protect the overall integrity. For example, a bridge deck can expand on hot days without buckling thanks to properly designed joints.

Safety is a top priority in any structure. Expansion joints reduce the risk of sudden failures caused by stress buildup or fatigue. In bridges, they prevent dangerous cracking or buckling under heavy traffic or temperature shifts. In pipelines, joints reduce strain on connections to pumps or turbines, lowering the chance of leaks or bursts. This protection keeps both the structure and its users safe.

Many expansion joints are designed for easy access and replacement. This feature simplifies maintenance and reduces downtime. Instead of costly repairs caused by damaged materials, joints can be inspected regularly and replaced if worn. This approach helps keep systems running smoothly and lowers long-term maintenance costs.

Expansion joints come in many materials and designs to suit different environments. For example, rubber joints absorb vibration in HVAC systems, while metal joints handle high temperatures in power plants. They can be customized to resist chemicals, moisture, or extreme weather. This flexibility ensures joints perform well regardless of setting, from underground pipelines to skyscraper façades.

Choose expansion joints tailored to your structure’s movement type and environment to maximize protection, safety, and maintenance ease.

Selecting the appropriate expansion joint is crucial to ensure a structure's durability, safety, and performance. Different projects have unique demands, so considering several factors helps in making the best choice.

● Type of Structure or System: Expansion joints for bridges differ greatly from those used in pipelines or buildings. For example, a bridge joint must handle heavy traffic loads and large temperature shifts, while a pipeline joint focuses on absorbing vibrations and thermal expansion.

● Expected Movement Range: Understand how much movement the joint must accommodate. Thermal expansion, seismic activity, or load-induced deflections all influence the size and flexibility needed.

● Environmental Conditions: Consider exposure to moisture, chemicals, temperature extremes, or UV radiation. Materials like rubber suit moderate conditions, while metal joints resist high temperatures and corrosive environments.

● Installation and Maintenance Access: Some joints require more complex installation or regular maintenance. Choose a joint type that fits the project’s practical constraints and maintenance capabilities.

● Load and Pressure Requirements: Especially for pipe joints, pressure ratings and load capacities must align with system demands to prevent failure.

Engaging engineers, architects, or expansion joint specialists early in the project ensures the right joint is specified. Professionals can:

● Assess structural movement accurately.

● Recommend materials and designs tailored to project needs.

● Provide insights on installation methods and long-term maintenance.

● Help navigate building codes and industry standards.

Their expertise reduces risks of improper joint selection, which can lead to costly repairs or safety hazards.

Many expansion joints can be customized to fit unique project requirements. Customization options include:

● Material Selection: Combining materials for enhanced performance, such as rubber with fabric reinforcements or metal with protective coatings.

● Size and Shape: Tailoring the joint dimensions to accommodate unusual movement ranges or architectural constraints.

● Additional Features: Adding fire resistance, waterproofing, or soundproofing capabilities depending on the building’s needs.

● Transition Assemblies: Designing factory-fabricated transitions to ensure continuity of seal between different joint types or building components.

Custom expansion joints optimize performance and longevity, especially for complex or high-demand structures.

Always evaluate movement type, environmental exposure, and maintenance needs before choosing an expansion joint to ensure optimal durability and safety for your project.

Installing expansion joints correctly is essential to ensure they function as intended. The process starts with precise measurement of the joint gap to accommodate expected movement ranges. The joint must be installed so it fully spans the gap, connecting all structural elements it bisects, such as slabs, walls, or pipes.

Key steps include:

● Surface Preparation: Clean and smooth surfaces where the joint will be installed. Remove dust, debris, and loose materials to ensure proper adhesion and sealing.

● Alignment: Position the expansion joint material accurately to allow for full movement without binding or restriction.

● Sealing: Use compatible sealants or fillers to waterproof and protect the joint. This prevents moisture intrusion and corrosion.

● Anchoring: Secure the joint system using appropriate methods that avoid damaging the surrounding materials, especially in delicate facades or finishes.

● Integration: Ensure the joint interfaces seamlessly with adjacent building components such as waterproofing membranes, fireproofing, or air barriers.

Following manufacturer guidelines and engineering specifications guarantees the joint’s durability and performance.

Regular maintenance keeps expansion joints in good condition and extends their lifespan. Inspect joints periodically for signs of wear, damage, or sealant failure. Common checks include:

● Visual Inspection: Look for cracks, gaps, or material degradation.

● Movement Testing: Confirm the joint moves freely without restriction or excessive stiffness.

● Seal Integrity: Check for leaks or water infiltration, especially after heavy rain or temperature extremes.

● Cleaning: Remove dirt, debris, or vegetation that could hinder joint movement or cause damage.

● Replacement: Replace worn or damaged components promptly to avoid structural issues.

Maintenance schedules depend on the joint type and environmental exposure but typically involve inspections at least annually.

Several errors can compromise expansion joint performance:

● Incorrect Sizing: Installing joints too small or large for the expected movement leads to joint failure or structural damage.

● Poor Surface Preparation: Dirty or uneven surfaces reduce adhesion and sealing effectiveness.

● Improper Sealant Use: Using incompatible or low-quality sealants can cause leaks and deterioration.

● Inadequate Anchoring: Overly aggressive fastening damages substrates; insufficient anchoring causes joint displacement.

● Ignoring Environmental Factors: Failing to consider temperature ranges, chemical exposure, or load conditions results in premature joint failure.

Avoiding these mistakes requires careful planning, skilled installation, and adherence to standards.

Always follow manufacturer instructions closely during installation and schedule regular inspections to catch early signs of joint wear or failure, ensuring long-term structural protection.

Expansion joints are crucial in construction, preventing structural damage and enhancing safety by absorbing movement and stress. They extend the lifespan of structures by reducing wear and tear. As construction demands evolve, expansion joints will remain vital for durability and safety. For top-quality expansion joints, consider Tianheng Company Overview, Expansion Joint Expert - Tianheng. Their products offer unique benefits, ensuring long-term performance and value in any construction project.

A: An Expansion Joint is a flexible connector that absorbs movement in structures due to temperature changes, vibrations, and loads, preventing damage.

A: Bridge Expansion Joints accommodate movement from traffic loads and temperature shifts, preventing deck cracking and damage.

A: Expansion Joints in pipelines absorb thermal expansion and vibrations, protecting pipes and equipment from stress and damage.

A: Rubber Expansion Joints are cost-effective, absorb vibrations, and reduce stress on connected equipment in HVAC and piping systems.

A: Metal Expansion Joints handle higher temperatures and pressures, while Rubber Joints are more flexible and cost-effective for moderate conditions.